Loss and efficiency of induction motor

What is loss?

We give electrical energy as input to

motor and mechanical energy as output. But the amount of energy we give input

is not entirely in the output.

{tocify} $title={Table of Contents}

That is, some amount of energy is wasted inside

the motor. And this is called loss of induction motor.

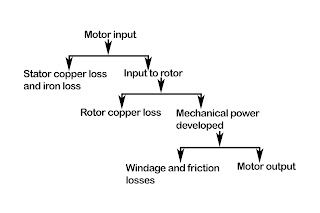

The figure below shows

the amount of loss from the induction motor to the electrical output to the

mechanical output.

How many types of loss?

According to the figure above, we see

4 types of losses. E.g.

1. Stator Copper

Loss

2. Stator Iron

Loss / Core Loss

3. Rotor Copper

Loss

4. Friction &

Windage Loss

We can also divide the loss of

induction motors into 2 more parts based on their nature. E.g.

1. Constant or

unchanging loss

2. Variable loss

Constant or unchanging loss

Losses that do not depend on the load,

that is, whatever type of load is applied to the shaft of the motor, will

always remain the same. The constant loss of motor can be measured through a no-load test. Constant loss can be further divided into 2 parts. E.g.

1. Stator Iron

Loss / Core Loss

2. Friction and

Windage Loss

Core loss

Eddie Current Loss and Hysteresis Loss

These two types of losses consist of Iron or Core Loss. By using laminated

cores we can reduce the amount of eddy current loss.

The laminated core reduces

the area and increases resistance. So the amount of eddy current is also

reduced a lot.

To reduce hysteresis loss, the core of

the motor should be made of low permeability material. Core loss depends a lot

on the frequency of the supply voltage. Because the supply voltage is always

given in the stator.

By core loss of motor, we mean a core loss of stator. This is

because the core loss of the rotor is so low that it can be ignored.

And since

there is no change in the supply frequency, the amount of loss is also fixed.

Hence it is called constant loss.

Friction and Windage Loss

This type of loss is due to motor

bearings and brushes. These losses depend on the speed of the motor. As the

speed increases, the Friction & Windage loss of the motor will also

increase.

And the speed of a three-phase induction motor is not usually

changed, so these losses are also called constant losses.

Variable loss

The copper loss of the stator and

rotor is the variable loss. The loss due to current flowing in the coil of the

stator and rotor is called copper loss. The level of current flow also changes

as the load changes.

As a result, the amount of loss is less - more. Hence

copper loss is called variable loss. Copper loss can be measured on an

induction motor by testing the blocking rotor. Suppose,

Stator current =

ISTA

Stator voltage =

ISTA

Rotor current =

IROOT

If the electrical power supply that we

give to the motor is PSUP, first, the stator enters the current in its coil. If

the electrical power supply that we give to the motor is PSUP, first the stator

enters the current in its coil and some energy from PSUP is expended as stator

copper loss, 3 (ISTA) 2R (three-phase motor is therefore multiplied by 3).

Then the current enters the core of

the stator where the stator core loss, 3 (VSTA) 2 / R occurs. Electrical power

then becomes mechanical power. The energy that remains in this state is called

air gap power, PAG.

The current then enters the rotor and the rotor loses some

energy in its coil as the rotor copper loss, 3 (IROT) 2R. Then after spending

some more energy as Friction & Windage Loss, we get the output power, POUT.

Efficiency of induction motor

Simply put, the ratio of output power

to input power is called efficiency.

Efficiency = Output Power / Input Power

A certain part of the amount of power or Psup that we gave to the induction motor is wasted

in different ways and then we get the output power i.e. Pout.

Now the ratio

of Pout to Psup will be called

the efficiency of the induction motor.

Efficiency = POUT / PSup ।

The relationship of efficiency with load is given below.